Design Style:Modern Place of Origin:Shandong, China

Brand Name:CM Material:Poplar,hardwood,pine,birch

Formaldehyde Emission Standards:E1,E2 Size:(900-6000)*(30-120)mm

Thickness:10-100mm Density:580-730kg/m3

Color:customized MOQ:1000sheet

Product Name:plywood PAYMENT:30%advance 70%balance

Delivery Time:25 Days Supply Ability:50000 sheets per day

Packaging Details

standard exporting packing with pallet or loose packing

Port:qingdao

Lead Time:

| Quantity(sets) |

1 - 200 |

>200 |

| Est. Time(days) |

25 |

To be negotiated |

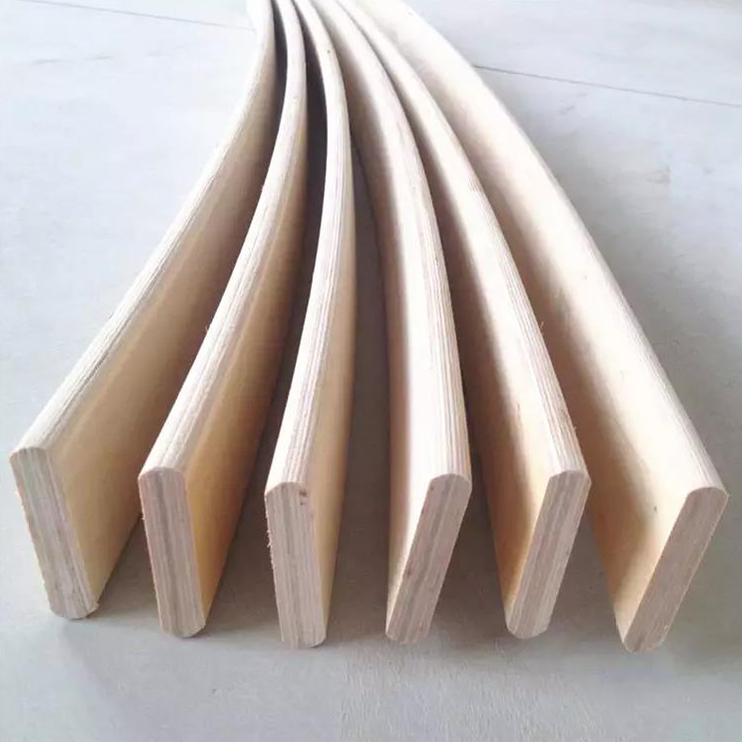

Curved Poplar/birch Plywood LVL slat bed frame / Bed Base

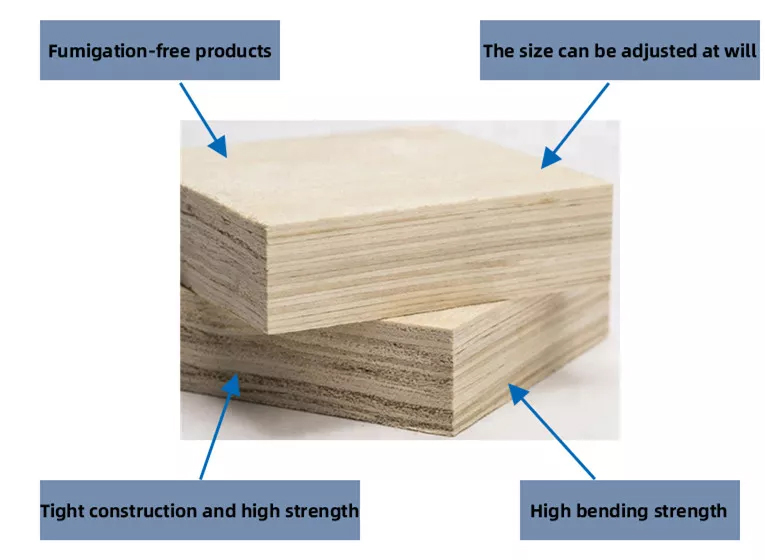

Laminated Veneer Lumber (LVL) is another type of plywood. It is made of multiple layers of thin wood (along the same direction of wood fiber), assembled with adhesives through hot-pressing.

Currently, the core veneers are mainly Poplar, Eucalyptus, Eucalyptus and Poplar mixed, Paulownia and Poplar mixed etc.

|

Product Name

|

Curved Poplar/birch Plywood LVL slat bed frame / Bed Base

|

Style

|

Bent straight

|

|

Size

|

Max lenght 6000mm,max width1200mm

|

Core

|

Pine,Poplar etc.

|

|

Edge processing

|

Curved

|

Moisture content

|

<12%

|

|

Face and back

|

Birch,Poplar or as requested.

|

Application

|

Bed,Sofa,Chair

|

|

Glue

|

MR/E0/E1/E2/WBP/Melamine

|

Place of Product

|

Shandong Province,China

|

Detailed Images

1.Choiceness Materials

Bed slat LVL is a structural product manufactured from thin peeled veneers of wood glued with a durable adhesive with the grain running parallel to the main axis of the member.We use fine material to produce and process Improve the quality of the source, bending ability.

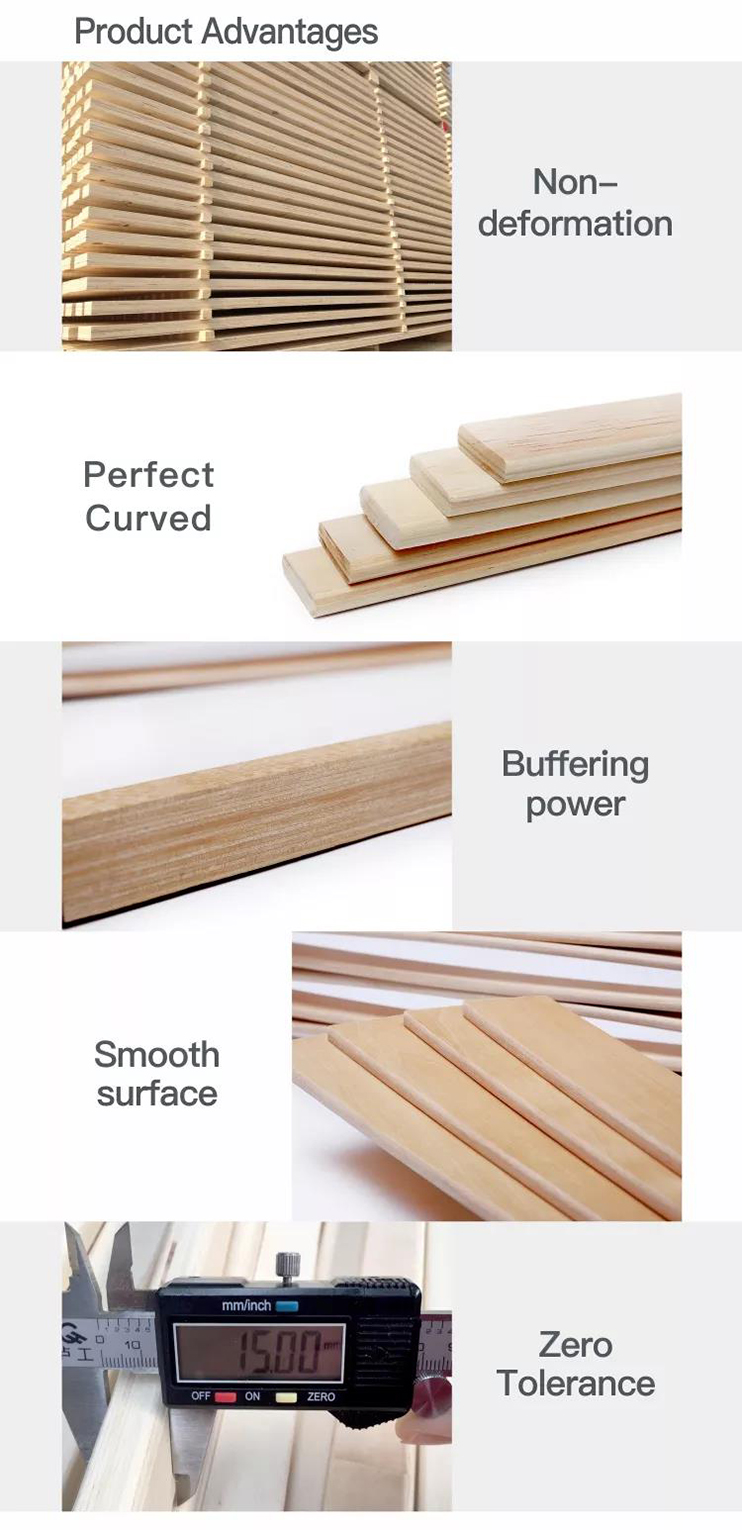

2.Sturdy and Durable

Panels of LVL are cut into structural members which have high strength and stiffness.It has the characteristics of high strength, stability and reliability.products green environmental protection.

3.Custom Size

For special manufacturing method, the size of LVL can be not restricted by log size or veneer specification, so the sizes is flexible, according to customer requirements production, convenient users according to their own needs to buy, low price.

Advantage

* High strength-to-weight ratio – more than 40 stronger than solid sawn products * High design values for bending, stiffness and shear strength * Resists shrinking, warping, splitting and checking * No defects to cut out and less waste on the job * Ordinary nail assembly – installs as easily as ordinary lumber

Previous:

Curved mdf Panel for Interior Wall Cladding

Next:

18mm Melamine Slatwall Grooved MDF/Slot MDF Board / Slotted MDF