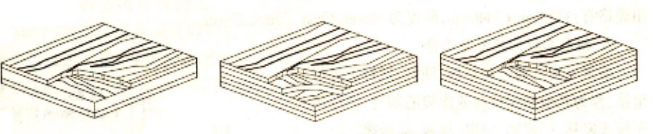

Plywood, also known as plywood, core board, three-ply board, five-ply board, is a three-ply or multi-layer odd-layer board material made by rotary cutting wood segments into veneer or thin wood shaved from wood, glued with adhesive, the fiber direction of adjacent layers of veneer is perpendicular to each other.

In the same sheet of plywood, veneers of different species and thicknesses are allowed to be pressed together at the same time, but symmetrical two layers of veneer require that the species and thicknesses be the same. Therefore, when looking at plywood, the middle veneer is the center and the veneers on both sides are uniform in color and thickness.

In the use of plywood, most of the major industrial developed countries use it in the construction industry, followed by shipbuilding, aviation, trunking, military, furniture, packaging and other related industrial sectors. China’s plywood products are mainly used in furniture, decoration, packaging, building templates, trunks, ships, and production and maintenance.

Length and width specifications are generally: 1220 x 2440mm.

Thickness specifications are generally: 3, 5, 9, 12, 15, 18mm, etc.

In the finished plywood, the inner layer of veneer other than the surface board is collectively called the middle board; it can be divided into short middle board and long middle board.

Common plywood veneer species are: poplar, eucalyptus, pine, miscellaneous wood, etc.

Plywood veneer can be classified according to appearance grade: special grade, first grade, second grade and third grade.

Special grade: flat surface specifications, no holes/seams/skins/dead joints, large burrs;

Grade I: flat board surface, no bark/bark holes, seams, knots;

Grade 2: The surface of the board is basically neat, with a small amount of bark and bark holes;

Grade 3: board surface length and width is not complete, clip bark, bark hole, defective more.

Plywood sheet is the outermost veneer used as plywood, divided into panels and backsheets.

The common wood species used as plywood veneer are: Augustine, mahogany, poplar, birch, red olive, mountain laurel, ice candy, pencil cypress, large white wood, tang wood, yellow tung wood, yellow olive, clone wood, etc.

Common plywood surface wood colors are: peach face, red face, yellow face, white face, etc.

Since plywood is made of veneer coated with glue in the direction of wood grain, pressed under heated or unheated conditions, it can overcome the defects of wood to a greater extent and improve the utilization rate of wood, thus saving wood.

Plywood is a multi-layer laminate, so it is much cheaper than solid wood.

The physical and mechanical properties of plywood in longitudinal and transverse directions are less different, which can greatly improve and enhance the physical and mechanical properties of wood, with good dimensional stability and resistance to warping and cracking.

Plywood can retain the natural texture and color of wood, with a flat shape and relatively large width, so it has a strong covering capacity and easy to apply construction.

Post time: Mar-02-2023